Drum filter systems for cutting fluids

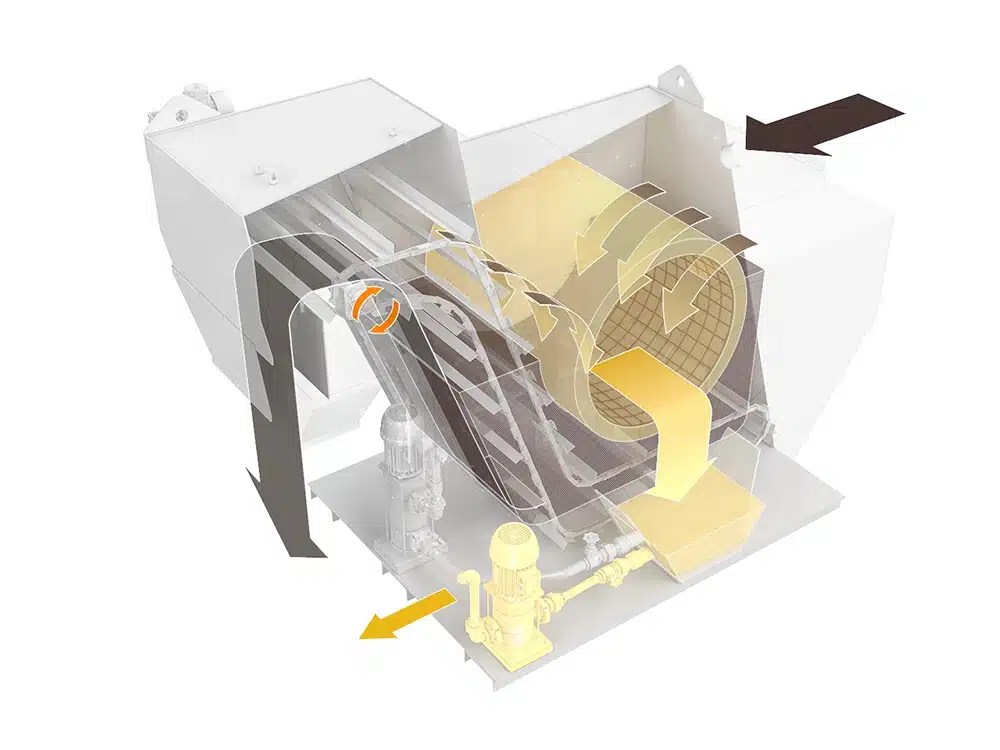

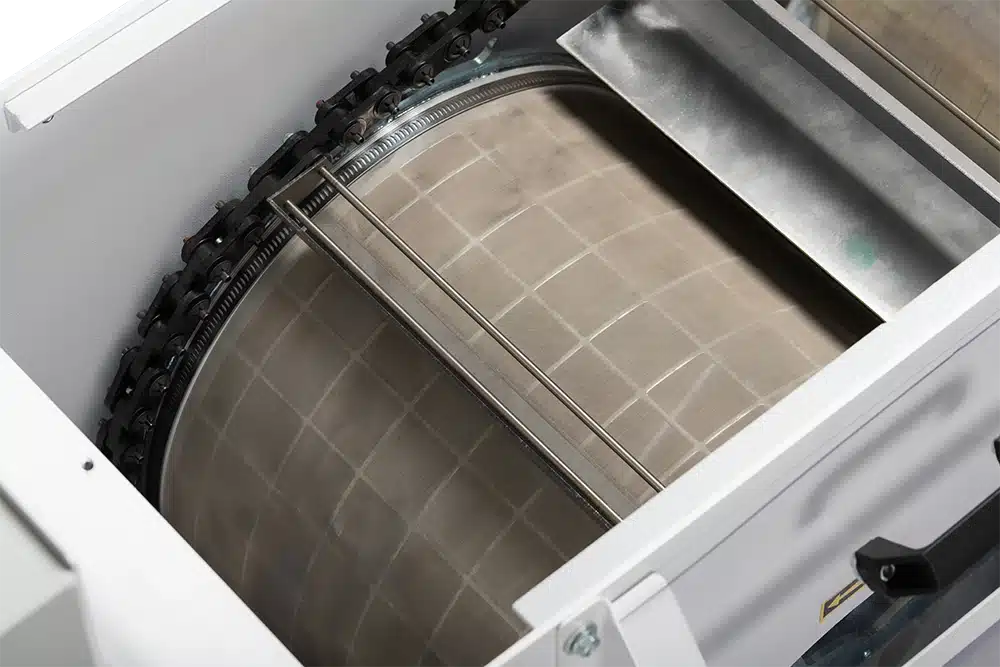

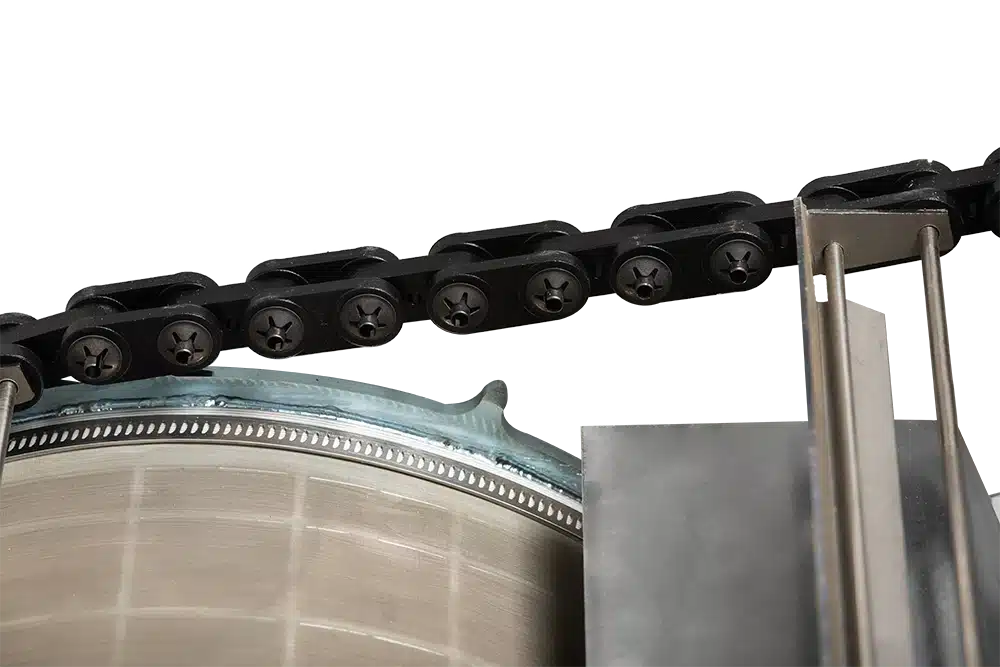

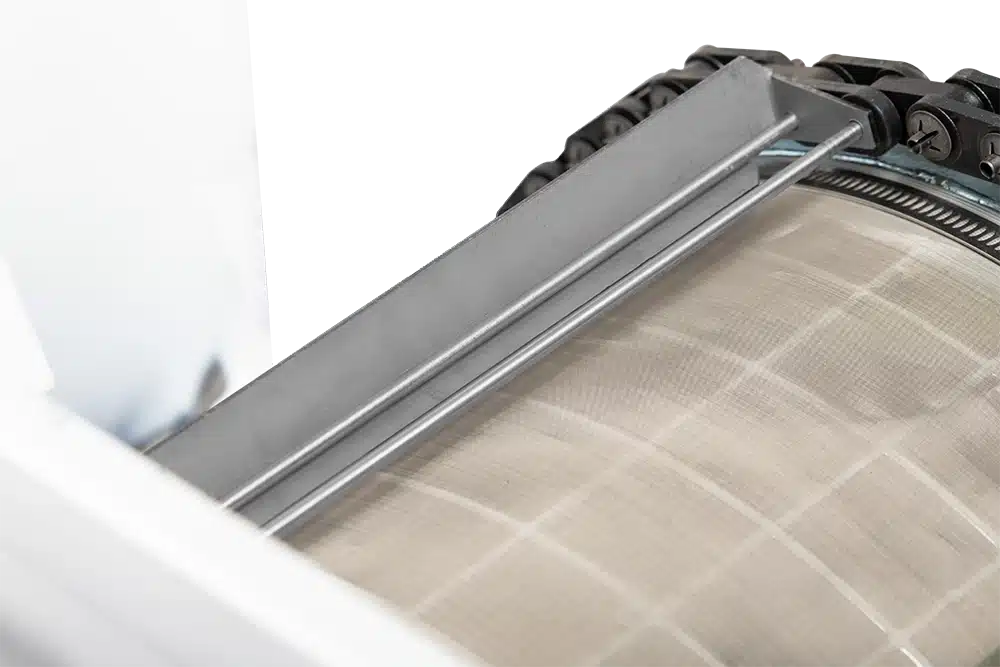

The SPRING filtration systems for cutting fluids, manufactured by LOSMA, are designed for production applications using cutting fluids, whether oil-based or emulsion-based. Equipped with a permanent media filter drum, an automatic cleaning system and a scraper for removing sludge and chips, the SPRING filter is recommended for production applications and particularly heavily contaminated liquids.

Performance and benefits

Investing in a SPRING filtration system allows you to:

- Extend the service life of the cutting fluid,

- Improve the surface finish of parts,

- Reduce tool wear,

- Limit clogging and wear of grinding wheels in grinding applications.

- Reduce maintenance costs.

The SPRING range consists of several models with different flow rates:

- 50 to 2000 L/min for 5% emulsion,

- 25 to 1000 L/min for full oil with a viscosity of 20cst at 40°,

- Nominal filtration threshold, 100µ as standard. Other media available on request.

A versatile and modular system

The SPRING filter is suitable for a wide range of machine tools such as:

- Numerically controlled machining centre,

- Numerically controlled turning centre,

- Milling machines,

- Lathes,

- Flat, cylindrical and centreless grinding machines

- Drilling machines

- Boring machines,

- Transfer machines

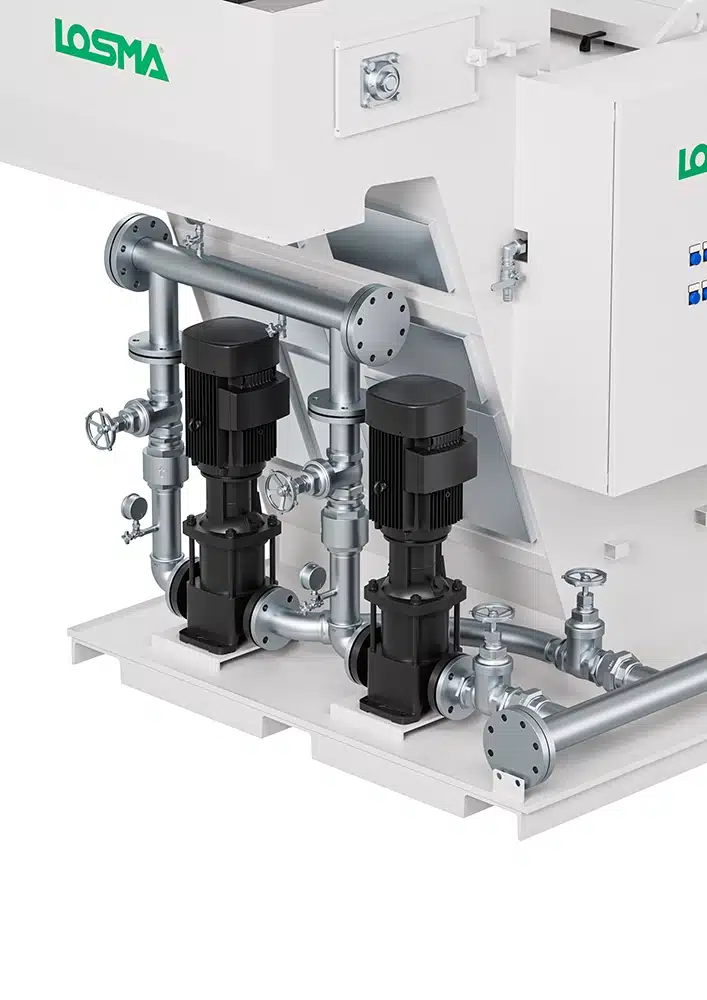

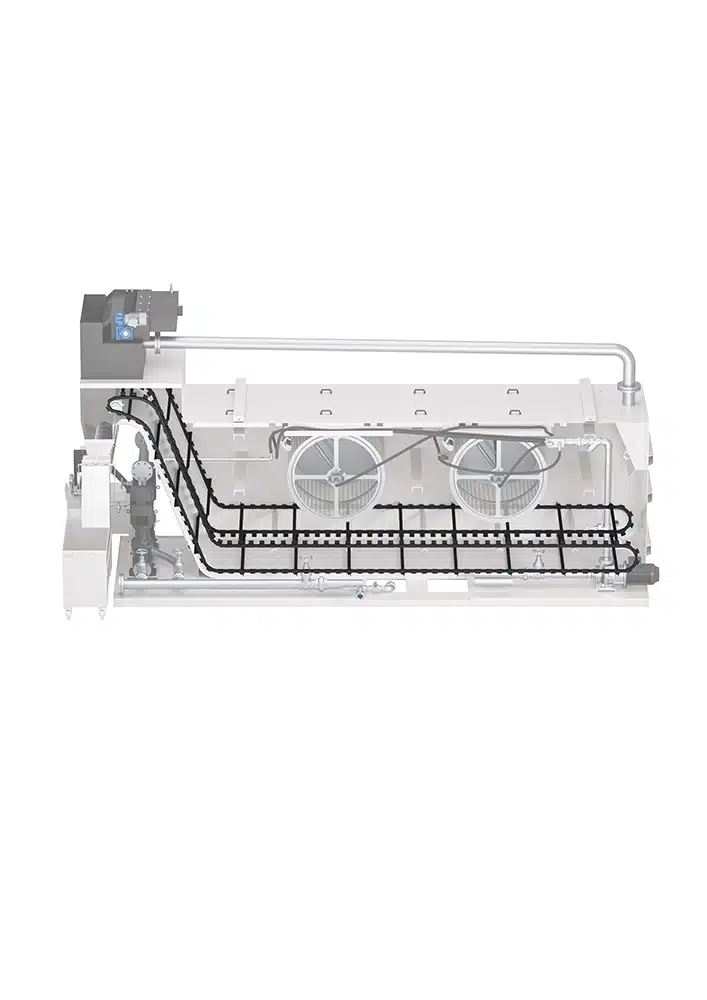

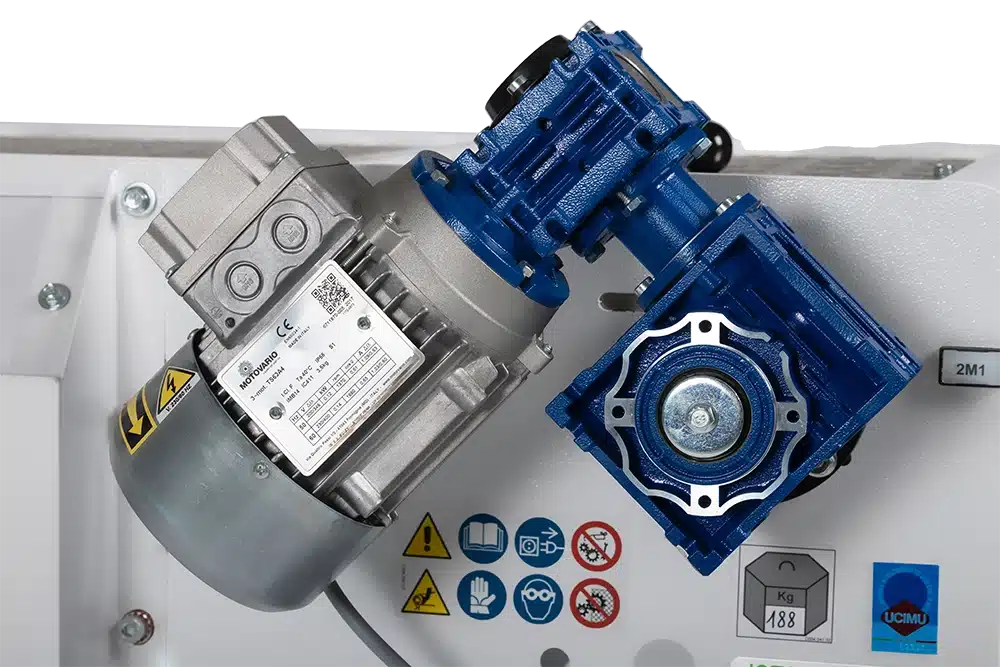

It is suitable for machine-side solutions as well as centralised systems. Its technology allows for compact or high-capacity solutions that are economical to use, as they require no consumables. The SPRING filter consists of a drum with a permanent filter cloth, a washing system and a scraper to remove sludge and chips.

The following options are available:

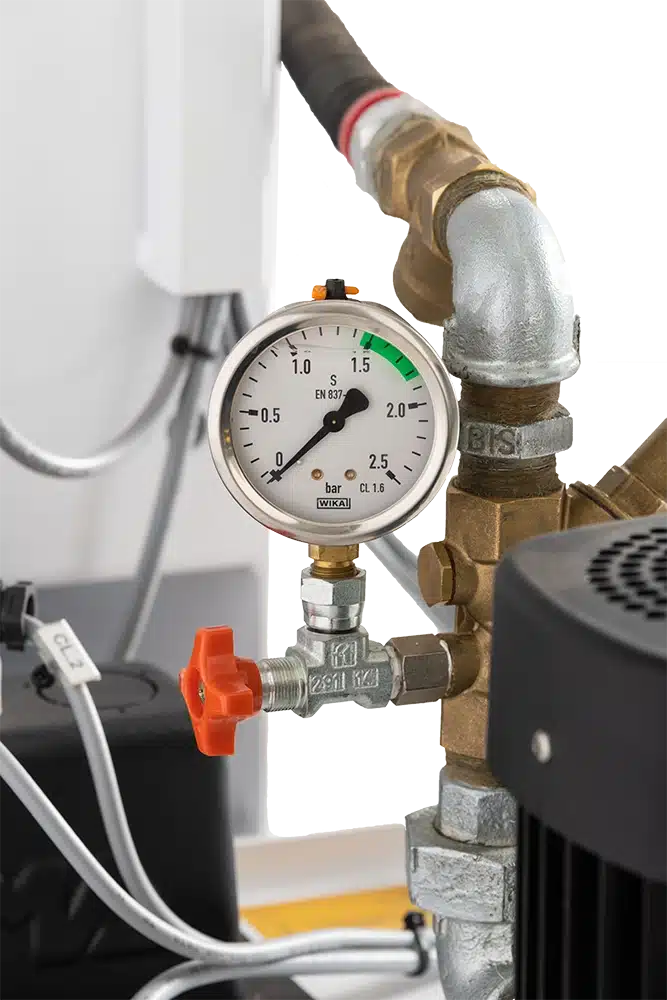

- Pre-filtration by magnetic separator,

- A cooling unit or exchanger to be connected to a chilled water network,

- An oil separator to remove foreign oils,

- A sludge compactor at the dredge outlet,

- Lifting tank,

- Custom-made tank,

- Control cabinet.

In addition to the SPRING filter, TECHNIFILTRE also offers ready-to-use solutions for installation on machines or for multiple machines depending on the flow rate.

TECHNIFILTRE support

TECHNIFILTRE supports you in your new or retrofit projects, whether for installation on a machine or for a centralised network, based on its product and application knowledge and its experience.

Documentation

- Technical sheet PDF