Hydrostatic filtration systems for cutting fluids

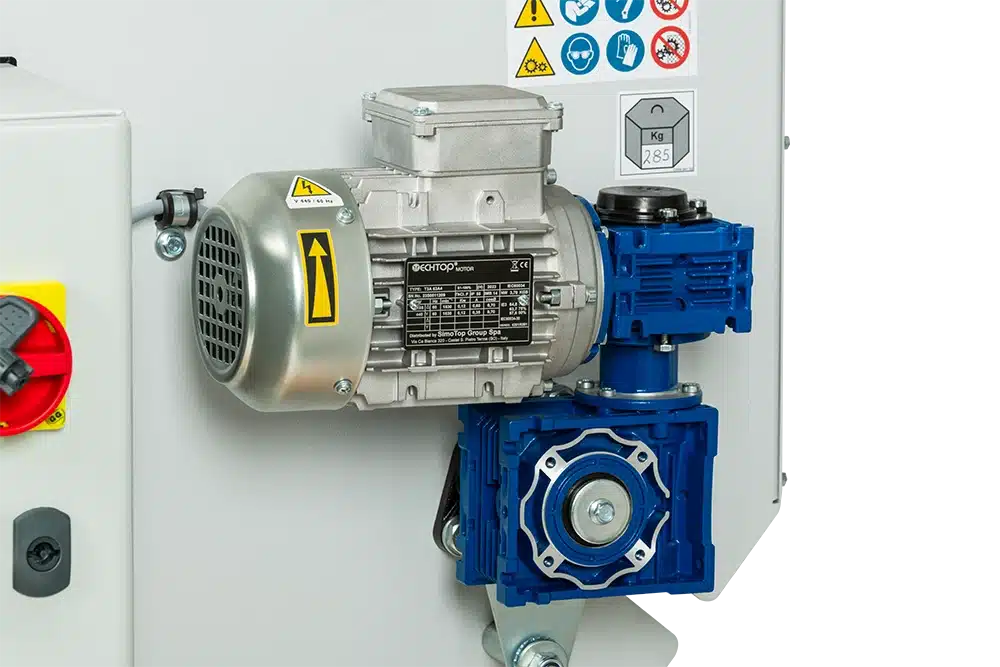

The MASTER filtration systems for cutting fluids, manufactured by LOSMA, are designed for production applications using cutting fluids, either oil-based or emulsion-based.

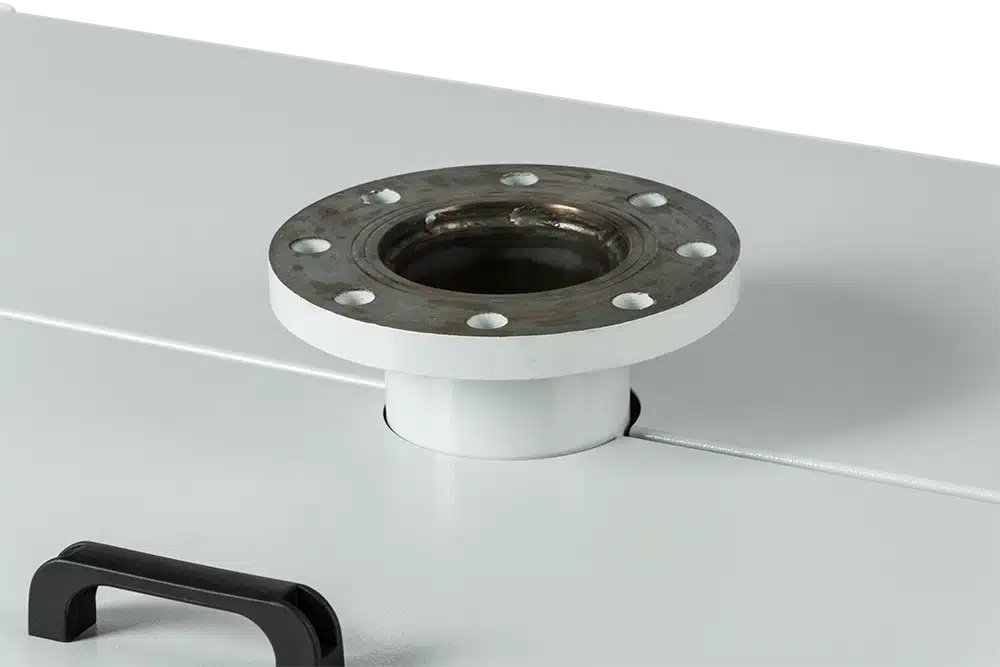

This MASTER uses gravity purification technology with a filter medium with high static charge for high efficiency. The saturation of the filter media is managed by a high level. The saturated media is discharged into the tank provided for this purpose. This filter media comes in the form of a roll that is installed on a support and unwinds automatically as it becomes saturated.

The MASTER filter is therefore a compact and easy-to-integrate solution that meets the filtration needs of production applications.

Performance and benefits

Installing a MASTER filtration system allows you to:

- Extend the service life of the cutting fluid,

- Improve the surface finish of parts,

- Reduce tool wear,

- Limit clogging and wear of grinding wheels in grinding applications.

- Reduce maintenance costs.

The MASTER range is divided into three ranges with several models offering different flow rates:

LOSMA MASTER model

- 400 to 2000 L/min for 5% emulsion,

- 200 to 600 L/min for full oil with a viscosity of 20 cst at 40°C

*LOSMA MEDIO-MASTER400 model

- 800 L/min for 5% emulsion

- 200 to 400 L/min for full oil with a viscosity of 20 cst at 40°C

LOSMA MINI-MASTER model

- 100 to 400 L/min for 5% emulsion,

- 60 to 200 L/min for full oil with a viscosity of 20 cst at 40°,

Flow rate with 35 g/m² filter media. Other media available on request.

A versatile and modular system

The MASTER filter is suitable for a wide range of machine tools, such as:

- Numerically controlled machining centre,

- Numerically controlled turning centre,

- Milling machines,

- Lathes,

- Flat, cylindrical and centreless grinding machines

- Drilling machines

- Boring machines,

- Transfer machines

It is suitable for both machine-side solutions and centralised systems. Its technology enables us to offer user-friendly and economical solutions. The MASTER filter is a gravity filter with high static load and filter media.

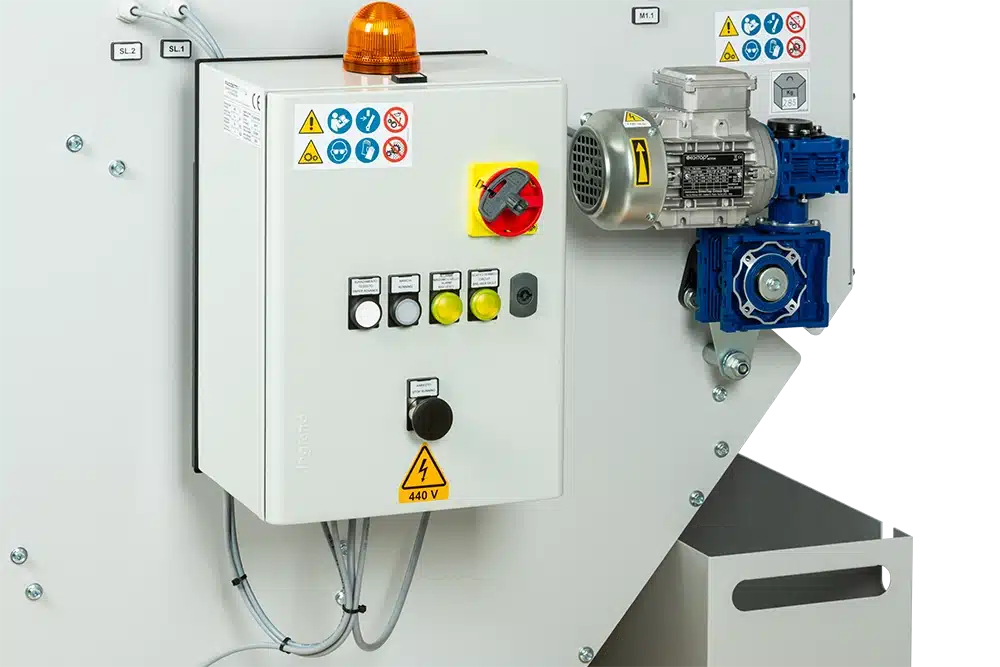

The following options are also available:

- Pre-filtering by magnetic separator,

- Roll end detector,

- A cooling unit or heat exchanger to be connected to a chilled water network,

- An oil separator to remove foreign oils,

- Lifting tank,

- Custom-made tank,

- Control cabinet.

TECHNIFILTRE support

In addition to the MASTER filter, TECHNIFILTRE offers ready-to-use solutions for installation on machines or for multiple machines depending on the flow rate.

TECHNIFILTRE supports you in your new or retrofit projects, whether for installation on a machine or for a centralised network, based on its product and application knowledge and its experience.

Documentation

- Technical sheet PDF