Given the current situation, improving productivity is one of the keys to revitalising production. Solufab understands this well and has installed Technifiltre-Losma mist filtration equipment in its machining centres. This has boosted the power and cutting speeds of the machines, all in a perfectly clean environment.

As the main point of contact for customers, manager Frédéric Sanchez supports his clients in the development of prototypes and tools as well as in small and medium-scale production. Technical machining of titanium, stainless steel and composites and the finishing of 3D-printed parts form the core of this Toulouse-based subcontractor’s activities. Equipped with several 5-axis centres, the latest of which is a Doosan VCF 850 SR, the company’s already well-stocked machine pool includes powerful equipment with high-pressure cooling, which delivers significant cycle time savings once the oil mist problem has been solved. Without extraction/filtration, productivity would be significantly impacted: a heavy atmosphere would fill the workshop every time the machine doors were opened.

The task of resolving this issue was entrusted to a specialist in machine tool filtration, Christian Strippoli from Technifiltre. Time savings in production are economic imperatives that are important to Solufab’s partners. In addition to the volume and flow rate of air to be treated, close to 1,000 m³/h per machine, the presence of machining residues such as titanium dust, composite carbides, volatile and hazardous substances is an important factor to be addressed.

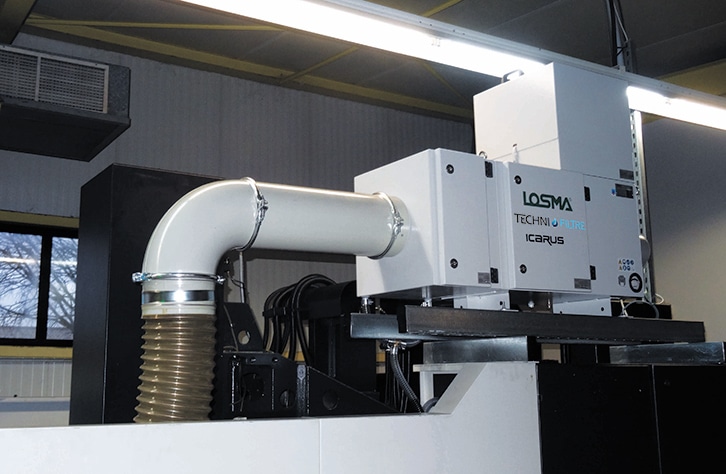

After studying the situation, the specialist identified three stages of air purification: pre-filtration, which stops light microparticles (small chips, dust, etc.); coalescing filtration, which treats oil mist (the Losma deep-field biofilter eliminates the risk of progressive clogging, this system allows the cutting fluid to be recovered and returned to the machine network), and finally, the H 13 absolute filter, which captures all residual fumes and micro-mists with an efficiency of over 99.95%. This stage is essential for the finishing machining of refractory materials, which disperse micro-particles into the air that are hazardous to health. Upon examining the machine layout, it was difficult to envisage a floor-mounted installation. Christian Strippoli therefore directed his customer towards Losma’s Icarus models. These can be positioned on top of the machine.

After a year of operation, the manager is fully satisfied. “The specialist’s offer was well thought out and economically attractive. What’s more, the productivity gains achieved are a major asset in winning new markets. The involvement of a specialist provides reassurance for the manager in his health and safety role. It has the advantage of maximising productivity gains in terms of cutting and feed speeds,” concludes Frédéric Sanchez.

The Technifiltre installation meets the development expectations expressed by Solufab’s management. Since the Losma Icarus equipment was commissioned, operator motivation has remained high. Productivity has increased to its maximum potential. The machines remain clean. Everyone is very satisfied to be using the latest generation of machines to boost quality and productivity in a healthy environment. To start afresh on a healthy and even more productive footing, Solufab is relying on a motivated team and high-performance resources to develop its customer base by cultivating its strengths: reliability and responsiveness.

Download the article published in the Special Aeronautics Edition of Machines Production